Repairs of engines and transmissions

Quality without compromise

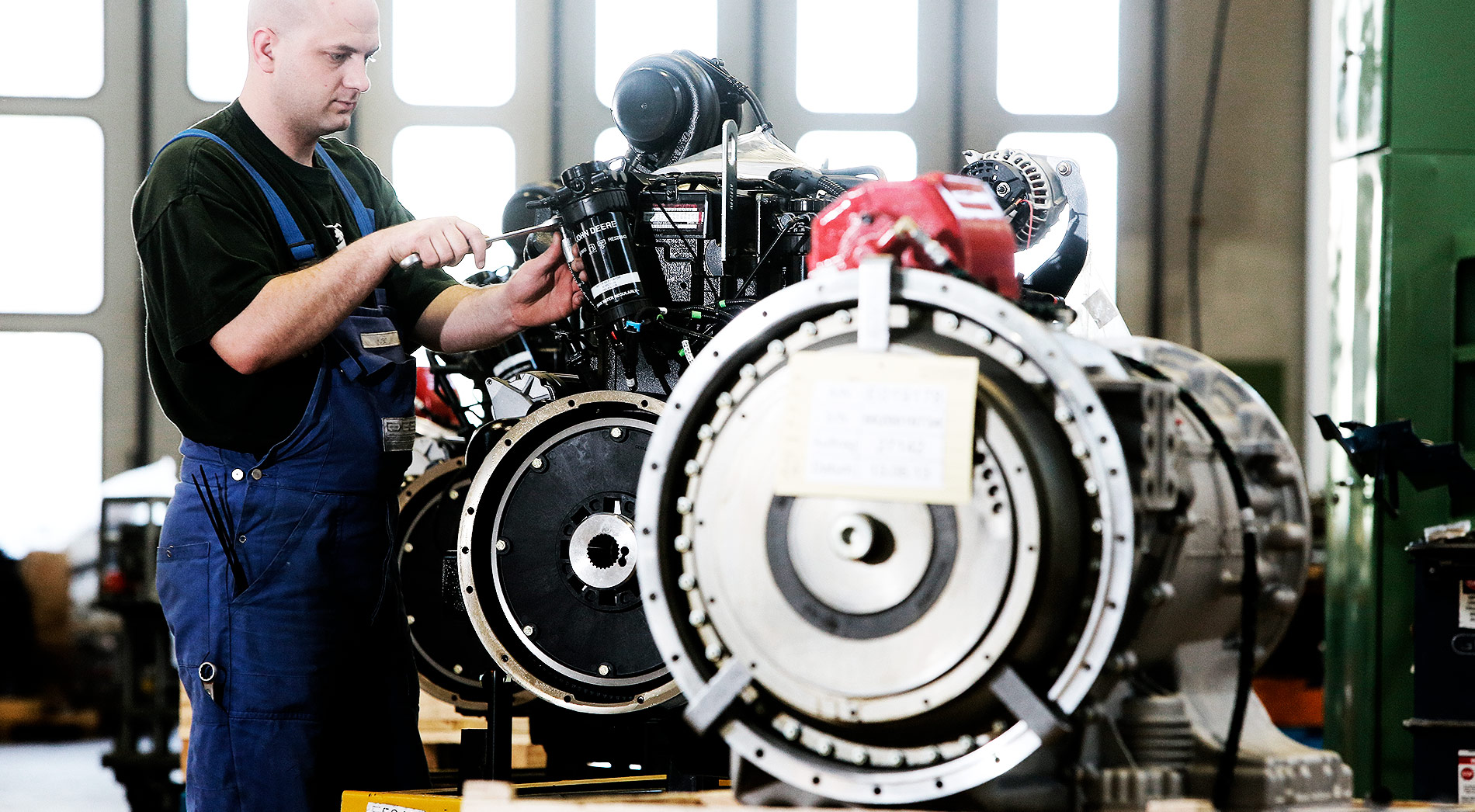

We have a modern and well-equipped workshop for the overhaul of complete aggregates as well as an engine and transmission test bench. Only original spare parts from the manufacturers are used for repairs. This also applies to our exchange products.

Flexibility

In the event of damage, we adapt to the needs of our customers. You have the choice between on-site repair and general overhaul in our workshop. Our qualified staff is available to explain the findings to you. Alternatively, we keep a permanent stock of 120 – 140 replacement units to get your machine back into operation quickly. Clear cost and availability statements will help you in your decision-making. Good quality service requires good personnel and the right spare parts! Our skilled personnel is trained regularly to constantly stay up to date.

Scope of services

All ‘second life’ products sold by our company are professionally repaired or overhauled. Following these processes, test bench runs are carried out under load on our own engine and transmission test benches. Every day, our employees & mechanics are on the road with appropriately equipped company cars nationwide from Flensburg to Garmisch. The in-house warranty administration for all products is just as natural for us as the constant expansion of the product-specific dealer networks. We are able to program the control units (ECM / ECU) for all electronically controlled units.

Trust and reliability

As an authorized partner, we carry out the complete warranty processing for our customers, from mechanical work to commercial processing.

Service

Transmission repairs

You want dependability in planning?

Time and costs are equally important variables for you?

We understand that! Rely on us.

Keep downtime low

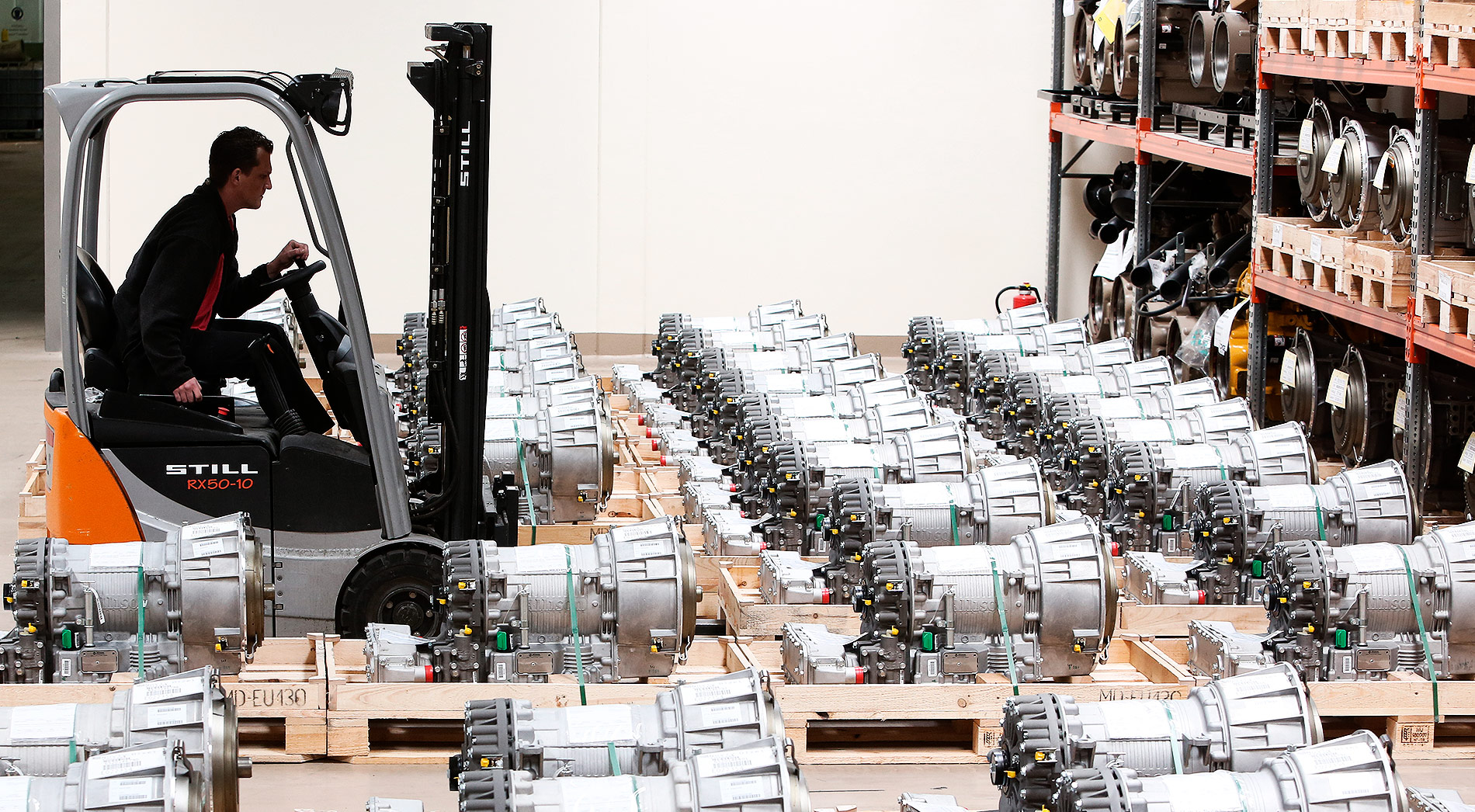

To keep downtimes as low as possible, we permanently stock a large number of different replacement transmission units for a wide range of applications and customer groups. From the small 1000/2000 in airfield equipment, to the 3000 series for municipal vehicles or the 4000 series for heavy vehicles, the delivery of replacement transmissions in 48 hours in a wide variety of designs is almost always possible. Even for the ‘big ones’ such as 6000 series transmissions for dump trucks or Allison’s largest 8000/9000 series transmissions for oilfield applications, refurbished units are available for immediate use. Reconditioning or overhauling with highest precision & minimum time helps our customers (service sector, municipal waste management companies, crane operators, bus industry or transport industry) to minimize costs.

Trust and reliability

As an authorized distributor, we carry out the complete warranty processing for our customers, from mechanical work to commercial processing.

Service

Engine repairs

Repairs according to maintenance stages or as required, complete overhauls of drive lines or so-called “inframe overhauls” (repair of drives in installed conditions): You decide!

We use the latest generation of diagnostic tools – but we also understand the controls of the earlier series (DDEC, DDDL or John Deere Service Advisor). Our goal is to simplify troubleshooting and reduce analysis costs and downtime.

References

MS Rheinstar

Matching replacement units as trunk or complete engines complete our range of services. For example, all JOHN DEERE 300 series engines from the agricultural applications (tractor and combine harvester) are available. The corresponding price list with scope of delivery and availability is available online for download.

Engine Compartment MS Rheinstar

2 main drives DDC S 60 – 390 KW each and 2 JOHN DEERE 6.8 L – 150 KW generator power each.

For John Deere or DETROIT DIESEL engines (2 or 4 stroke) all common engines can be supplied in exchange. Please ask us for the reference list. Complete service & maintenance packages (e.g. for fire pump units in large production sites) round off our service.

Ship, Oil Field, Dump Truck …

DDC 16 V 149 – 40 L Displacement – 1500KW@2000U/min

We also handle the bigger stuff!

Artic Oil Field or Offshore Platform

No matter what… we can repair it. Here its a drill rig with a DDC 16 V 149 and an Allison DP 8963

Service

Diagnostics – proactive , sustainable, resource-saving

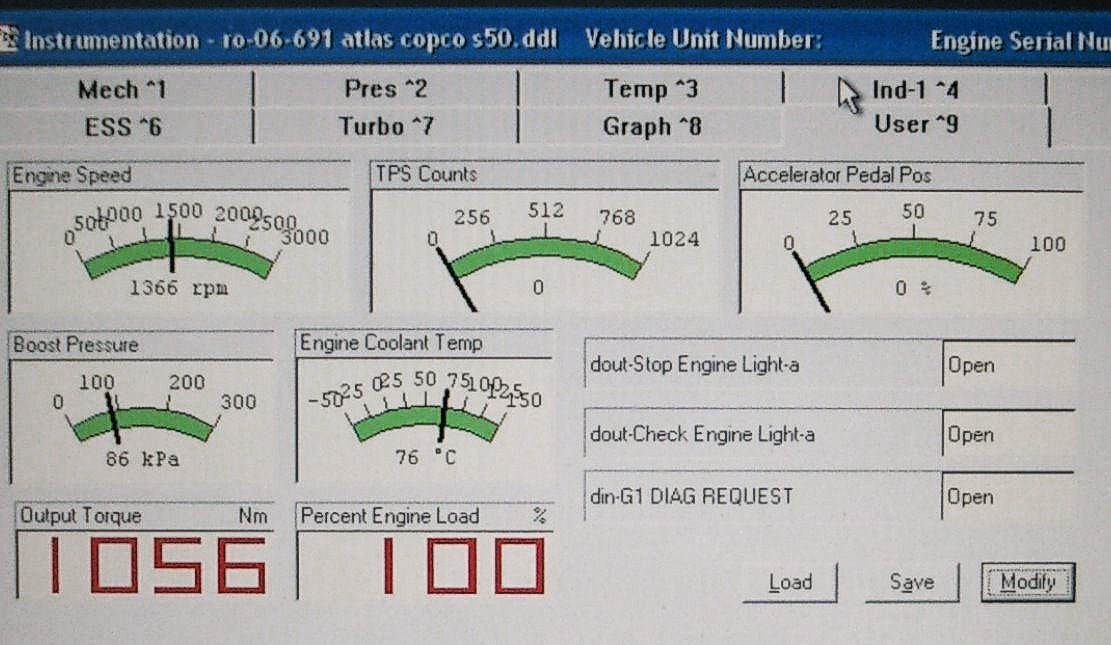

The analysis of faults is carried out including function diagnostics and software. For example, tachograph data is also used to determine fuel consumption, charging cycles or speeds.

References

Dump truck

40-ton class equipped with a Detroit Diesel S 60 and an Allison HD 4560

Online diagnosis – data recording

Diagnosis of the running culture, engine parameters and fault memory are indispensable benchmarks in the final product inspection.

DGS customer service vehicle in use

here in front of JOHN DEERE 6000 series tractors with 6.8L engines

Pressure gauges

As part of repairs and overhauls of automatic transmissions, the control blocks (responsible for the automatic upshifts and downshifts of the individual gear ratios) are put through their paces.

John Deere Reman Engines

Trainings

Spare Parts

Contact

Your contact for repairs

Our team is ready for the aggregates in the models of major original equipment manufacturers as well as for special and custom vehicles.

Benedikt Gerstenberger

Customer service John Deere

Phone +49 6131 5807-735

Andreas Schöller

Product support manager transmissions

Phone +49 (0) 6131 5807-730